Carbon electrode

- Electrical resistance ≤(μ.Ωm):28

- Bulk density ≥(g/cm 3):1.63

- Flexural strength ≥(Mpa):5.0

We're here to help:Easy ways to get the answers you need.

You may also want to see

This product is suitable for electric arc furnace. Suitable for the efficient production of silicon metal, nickel-iron alloy and yellow phosphorus, which is energy saving, environmentally friendly product, used in the calcium carbide, ferroalloy submerged arc furnace, also can greatly reduce the power consumption, and pollution.

Full graphitic carbon electrode is a new product, our company independent research and development, suitable for the submerged arc furnace smelting, a replacement product based on the traditional basis of anthracite as the base material carbon electrode. Full graphitic carbon electrodes use graphite scrap, anthracite as raw material, coal tar pitch as a binder, via calcinations, ingredients, kneading, pressure type, roasting, graphitization, machining in the electric arc furnace it could release electricity arc to melt the conductor.

Carbon electrode properties:

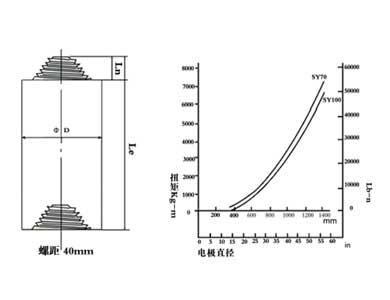

In order to make better used performance, two electrodes must be closely connected. Keep the surface between connecting thread and work side clean, and use appropriate torque to make good contact between connector thread and the end face of electrode. Current could be through evenly with less additional energy consumption. In order to ensure sufficient mechanical strength to overcome the thermal and mechanical stresses caused by external factors in the furnace.

Correct torque can tighten the connector better. Our company has many years practical experience in nipple's thermal and mechanical research, also can recommend the best appropriate torque according to the characteristics of the smelting furnace and operating conditions.

Right two curves (SY70, SY100) representing the different torque of two types electrode's diameters:

| Nominal Dia (mm) | Real Dia.(mm) | Length(mm) | ||||

| mm | inch | MAX | MIN | Black Partial MIN | Length | allowed deviation |

| 780 | 30.7 | 782 | 778 | 774 | 2000/2200/2400 | ±100short rod-400 |

| 800 | 31.5 | 802 | 798 | 794 | ||

| 850 | 33.5 | 852 | 848 | 842 | ||

| 870 | 34.5 | 872 | 868 | 862 | ||

| 900 | 35.4 | 902 | 898 | 892 | ||

| 920 | 36.2 | 922 | 918 | 912 | ||

| 960 | 37.8 | 962 | 958 | 952 | ||

| 1020 | 40.2 | 1022 | 1018 | 1012 | 2200/2600/2800 | ±100short rod-400 |

| 1060 | 41.7 | 1062 | 1058 | 1052 | ||

| 1100 | 43.3 | 1102 | 1098 | 1092 | ||

| 1146 | 45.1 | 1148 | 1144 | 1138 | ||

| 1197 | 47.1 | 1199 | 1195 | 1189 | ||

| 1250 | 49.2 | 1252 | 1248 | 1242 | ||

| 1272 | 50.1 | 1274 | 1270 | 1264 | ||

| 1305 | 51.4 | 1307 | 1303 | 1297 | ||

| 1321 | 52 | 1323 | 1319 | 1313 | ||

| 1400 | 55.1 | 1402 | 1398 | 1392 | ||

| Note: the diameter and length could be accorded to the agreement. The proportion of short rod electrode should be less than 10% |

||||||

| Item | Nominal diameter/mm | ||||

|

|

Unit | S Grade | G Grade | ||

| 780~960 | 1020~1400 | 780~960 | 1020~1400 | ||

| Electrical resistance ≤ | μ.Ωm | 28 | 29 | 28 | 30 |

| Bulk density ≥ | (g/cm 3) | 1.63 | 1.62 | 1.65 | 1.65 |

| Flexural strength ≥ | Mpa | 5.0 | 48 | 5.2 | 5.5 |

| CTE≤ | (10-5/℃) (100℃-600℃) | 3.8 | 3.8 | 3.6 | 3.6 |

| Elastic modulus ≤ | Gpa | 4.2 | 4.2 | 4.0 | 4.0 |

| Ash ≤ | % | 1.5 | 1.5 | 1.5 | 1.5 |

| Note: The coefficient of thermal expansion, modulus of elasticity just for reference | |||||

| Nominal Dia | SGrade | GGrade | ||

| Suggested current | Suggesteddensity of current | Suggested current | Suggested current | |

| (mm) | /A | (A/cm2 ) | /A | (A/cm2 ) |

| 780 | 30000-36000 | 7.8-9.4 | 36000-43000 | 9.3-11.3 |

| 800 | 35000-42000 | 7.4-8.8 | 42000-50000 | 8.9-10.5 |

| 870 | 40000-43000 | 7.0-8.0 | 48000-52000 | 8.4-9.6 |

| 900 | 41000-48000 | 6.5-7.5 | 49000-55000 | 7.9-9.0 |

| 920 | 41000-48000 | 6.2-7.1 | 49100-58000 | 7.8-9.0 |

| 960 | 44000-50000 | 6.2-7.1 | 53500-60000 | 7.4-8.5 |

| 1020 | 46000-52000 | 5.8-6.6 | 55000-62000 | 7.1-7.8 |

| 1060 | 49000-55000 | 5.7-6.5 | 59000-62600 | 6.8-7.5 |

| 1100 | 52000-58000 | 5.6-6.3 | 62000-70000 | 6.6-7.4 |

| 1146 | 55000-63000 | 5.5-6.2 | 66000-76000 | 6.4-7.3 |

| 1197 | 60000-68000 | 5.4-6.1 | 72000-80000 | 6.4-7.2 |

| 1250 | 61000-72000 | 5.3-6.0 | 73000-80000 | 6.3-7.0 |

| 1272 | 62000-74000 | 5.0-5.8 | 74000-85100 | 5.9-6.7 |

| 1305 | 63000-76000 | 4.9-5.8 | 76000-89600 | 5.8-6.7 |

| 1321 | 65000-78000 | 4.5-5.6 | 78000-88900 | 5.8-6.5 |

| 1400 | 65000-80000 | 4.2-5.2 | 78000-92300 | 5.4-6.0 |

PLEASE FILL IN YOUR CONTACT INFORMATION